Custom Shaped Wire

Our cutting-edge shaped wire rolling mills allow us to meet the demanding dimensional tolerances your business requires. Ulbrich has near limitless capabilities to produce custom shaped wire profiles for any application.

Shaped Wire Gauges Offered

Gauge Range

0.005” to 0.335″ (0.120mm to 8.509mm)

Width Range

0.035” to 1.50” (0.89mm to 38.46mm)

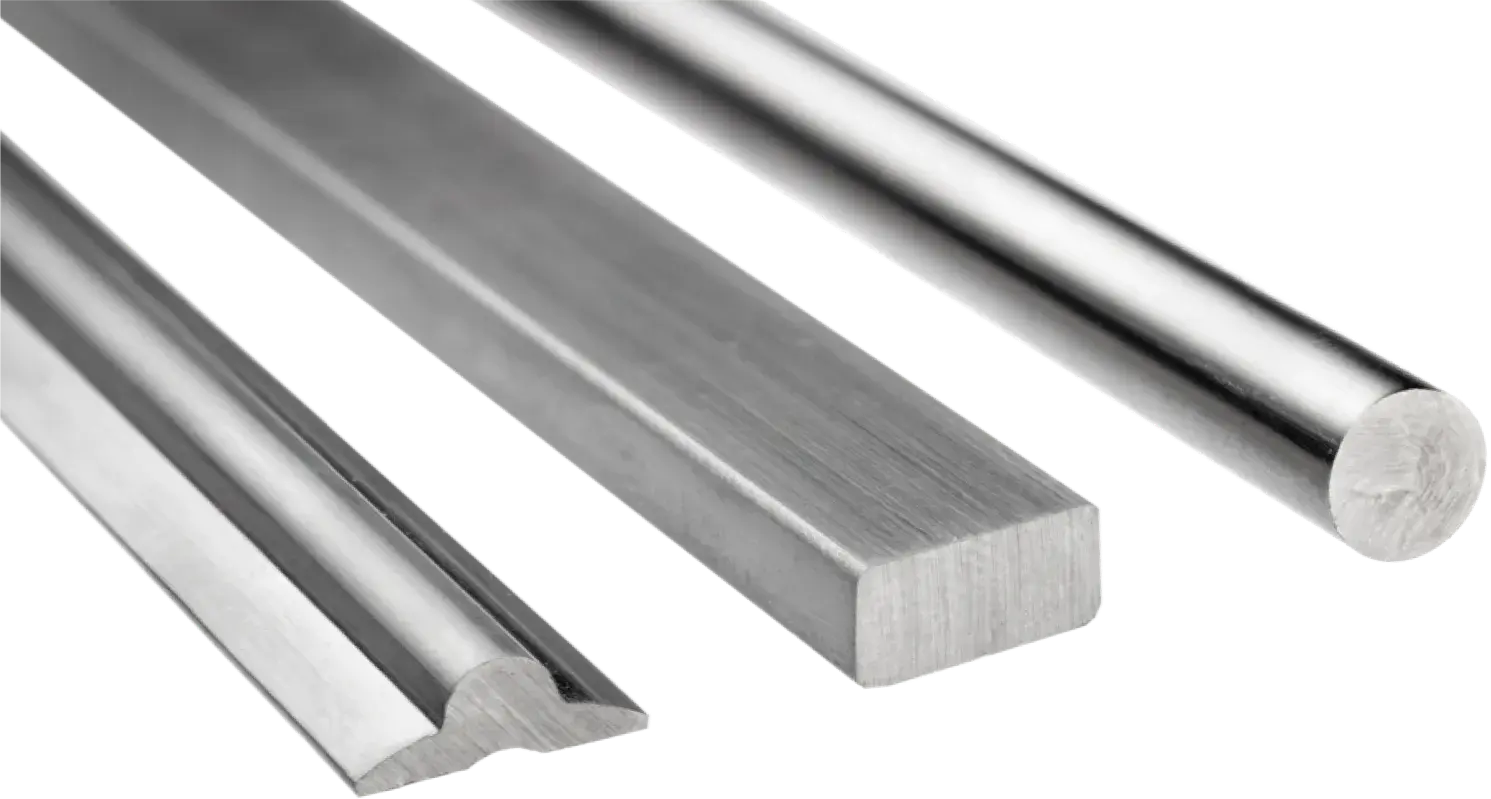

Common Shapes & Custom Wire Profiles

60° Keyway Triangle Wire

Bevel

Blade

D-Wire (Half, Large, Small)

Dog Bone

Multi-Gauge Strip

Rolled Flat Wire

Seal Strip

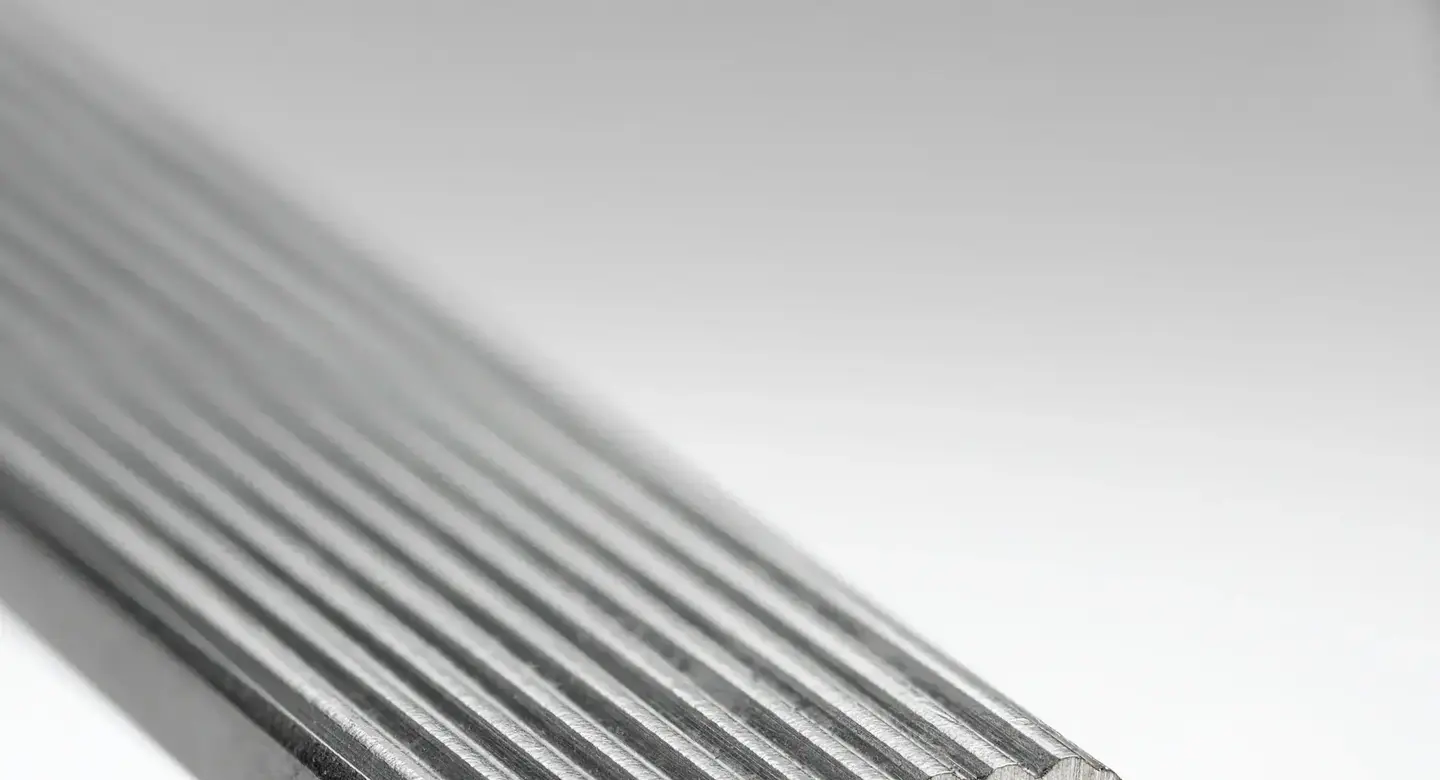

Serrated Shape

Star Wire

Symmetric & Asymmetric Vanes

Wedge Wire

And many, many more!

If you can dream it, chances are we can shape it!

If you have an idea, drop your sketch, design, or description, and our experts will contact you to make your vision a reality for your company.

Our Advantages

- Net or Near Net Shapes

- Close Dimensional Tolerances

- Achieve Specific Tensile/Yield/Temper Range Requirements

- Intricate Specialty and Custom Edges

- Continuous Coils

- No Burr

- In-Process Gauge and Measurement

- State of the Art, In-House Tooling Facility

- Improved Die Wear

Alloys Available

Stainless Steels

Nickel Alloys

Cobalt Alloys

Titanium Alloys

Carbon Steel

Aluminum Alloys

Nitinol

Special Metals

And More!

Get a quote

Thanks for your interest in Ulbrich Shaped Wire! Please fill out the form to request a quote for a custom-shaped-wire product.

Markets We Serve

Applications for our custom-shaped wire include consumer and industrial applications, wedge wire for the oil & gas industry, heat exchanger components, power generation seals, and much more.